The cost-effective management of weld quality and integrity has been a major challenge in the development and application of weld technology. The history of the application of welding has provided many examples of the consequences of weld failures from ships to pipelines and offshore rigs.

The solution to the problem has been the creation of detailed weld specifications and codes of practice which aim to establish validated weld procedures and welder competency. When the codes and specifications are followed there can be a reduction in the subsequent weld inspection. In addition, using a validated weld procedure and an approved welder provides a guarantee that all welds will meet the specified quality requirements and results in the production of cost effective durable welds that will meet the future service conditions.

The main specifications are:

- ASME IX

- EN ISO 15614-1 & 15614-2

- EN ISO 9606-1 & 9606-2

- AWS D1.1/D1.1M

- AWS D1.2/D1.2M

- API 1104

At MSL we have the accredited procedures to allow us to provide the following mechanical testing during a welding assessment test:

Tensile testing

Cross weld tensile testing

Bend testing

Charpy Toughness

Macro and Micro examination

Volume fraction

Hardness Surveys

Corrosion – Pitting/Crevice resistance test or intergranular corrosion test.

Weld Specifications ISO

The diagram below shows the relationships between the various ISO weld specifications which are displayed in the conventional presentation/format used by engineers for training purposes. It is clear that there is a holistic coverage of all the aspects of welding where control is needed and by appropriate application of these standards welds which have the durability and integrity for service performance can be produced.

Weld procedure and welder approval sequence of events

- Develop a Preliminary Welding Procedure Specification (p WPS)

- Carry out a welding procedure test witnessed by an appropriate Inspector.

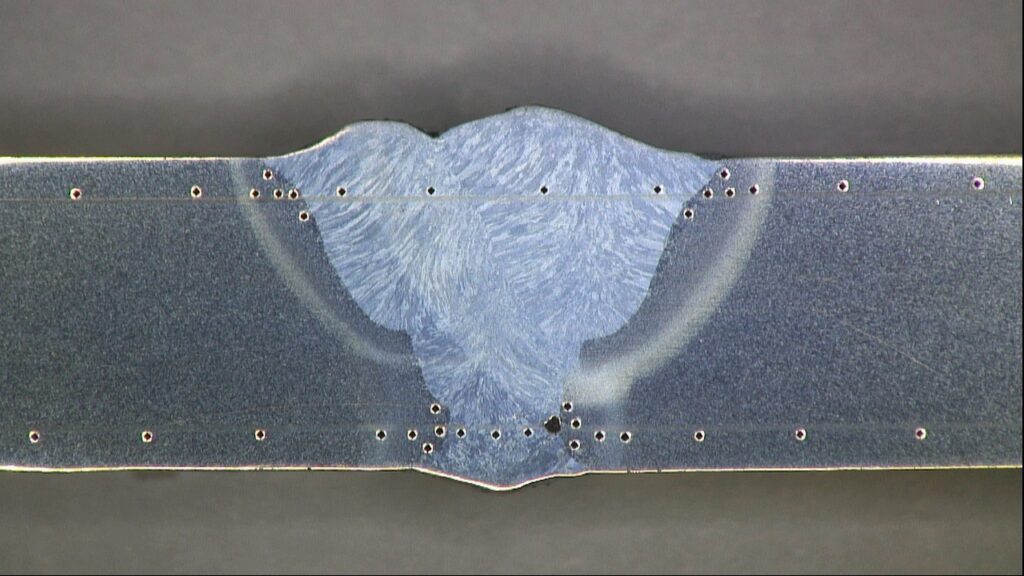

- Carry out NDT and mechanical testing to validate the weld procedure and prepare a Welding procedure qualification record (WPQR)

- Prepare a Welding Procedure Specification (WPS) based on the WPQR

Purpose and application of the Welding Procedure Qualification Record (WPQR):

The WPQR is a set of documents/technical file comprising of a WPS detailing the actual welding parameters recorded during the qualification test (i.e. those shown on the initial p WPS), the results of any non-destructive and destructive tests required by the standard, the material certification for the test piece and the subsequent range of qualification if all tests are proven satisfactory. The range of qualification is generally based on those variables which could have a significant effect on the metallurgical properties of a finished weld, including:

• Material type and thickness

• Welding process

• Type of welding consumable

• Welding position

• Welding heat input

• Type of joint (i.e. butt weld, fillet weld etc)

The range of qualification is an important part of the WPQR since this enables a single WPQR to be used to qualify an unlimited number of WPS