MSL offer a comprehensive range of mechanical testing, for further details please contact us.

For the full list of our UKAS Accredited testing please select the link below:

Metaltech Services – UKAS Schedule of Accreditation

IZOD impact testing

An important mechanical test that we retain UKAS accreditation on is a 300J swing energy Izod impact test. This allows us to assist with the testing in accordance with old UK industrial drawings and specifications that were initially developed and validated using the British developed Izod test.

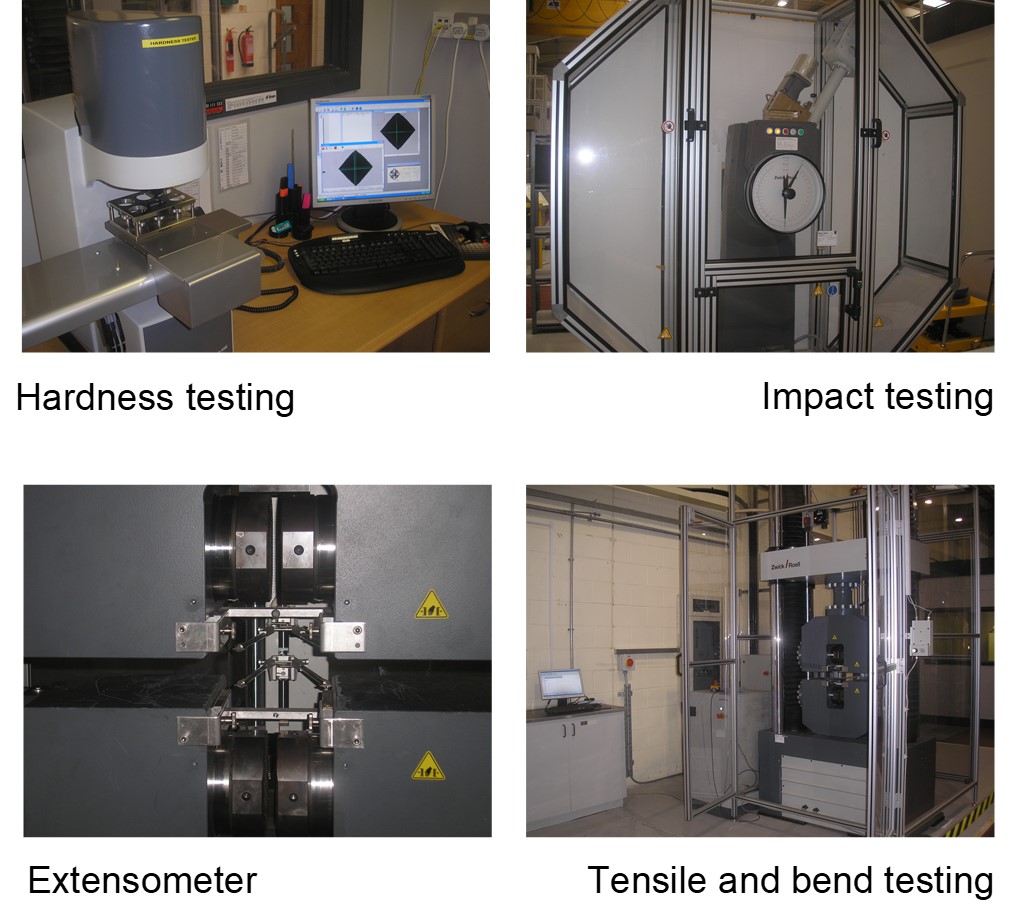

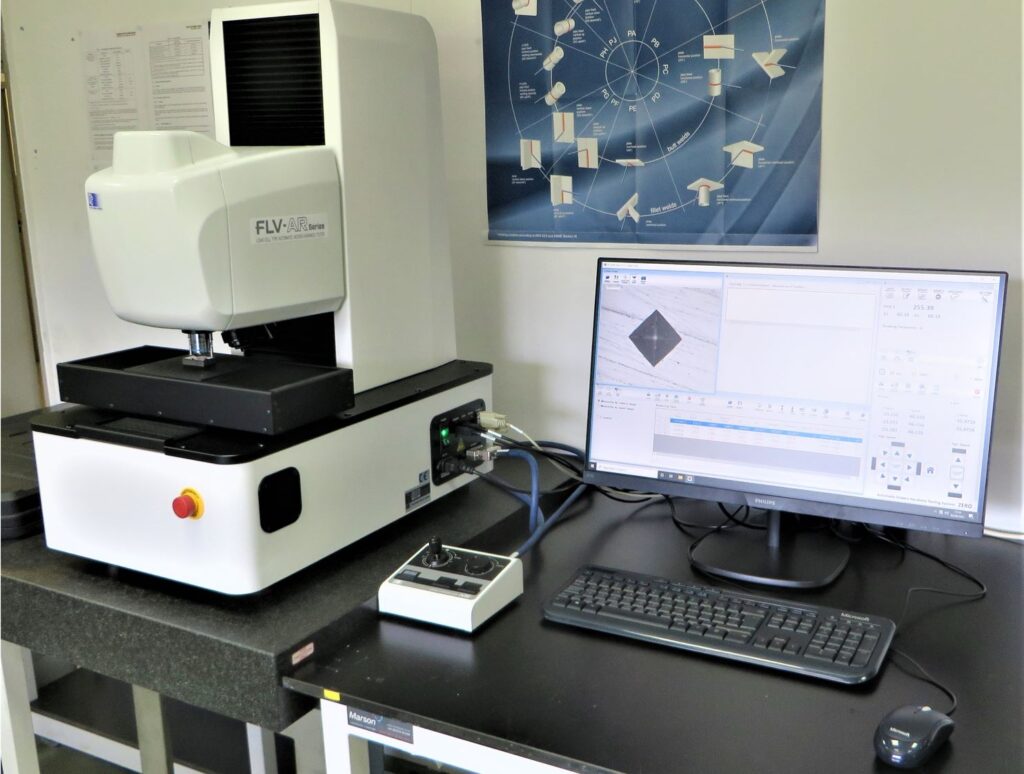

The range of test equipment and mechanical test area layout is shown in the photograph below