Hot tensile testing is carried out in accordance with BS EN 6892 (Metallic Materials – Tensile Testing- Part 2 Method of testing at elevated temperatures) or ASTM E21 (Standard Test Methods for Elevated Temperature Tension Tests of Metallic Materials)

The Hot Tensile Test (HTT) allows the measurement of the strength and tensile ductility at high temperature. The elevated temperature properties of materials are important in many applications such as oil and gas, power generation plant, aerospace, and automotive. The oil and gas industry have future plans to exploit oil and gas which involves deep wells with higher temperatures and pressures. It will be essential to carry out hot tensile tests on steels used for these applications. The tests on these materials will involve temperature that range from 50 to 300°C.

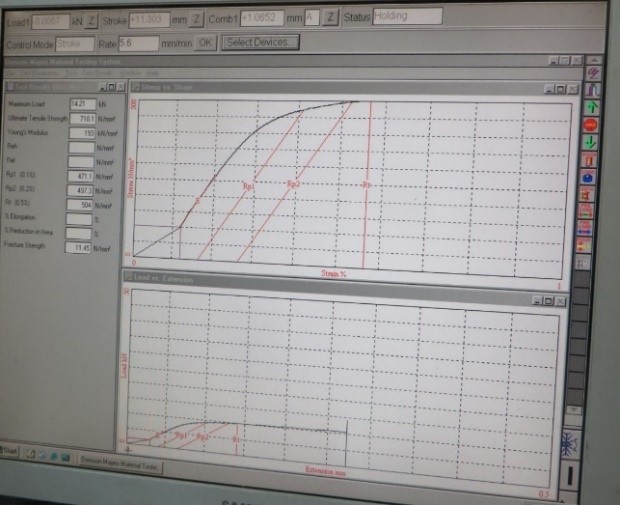

The hot tensile test is carried out by using a furnace/oven fitted onto the tensile testing load frame that allows the test specimen to be placed into the hot zone and to be tested. To measure the proof strength an extensometer is fitted to the specimen. Testing to ASTM E21 requires a dual averaging extensometer. A typical test would consist of heating to temperature and holding for 10 minutes after the extensometer has stabilized prior to testing. There should be a minimum of two thermocouples attached to the specimen and the temperature should be within +/- 2°C