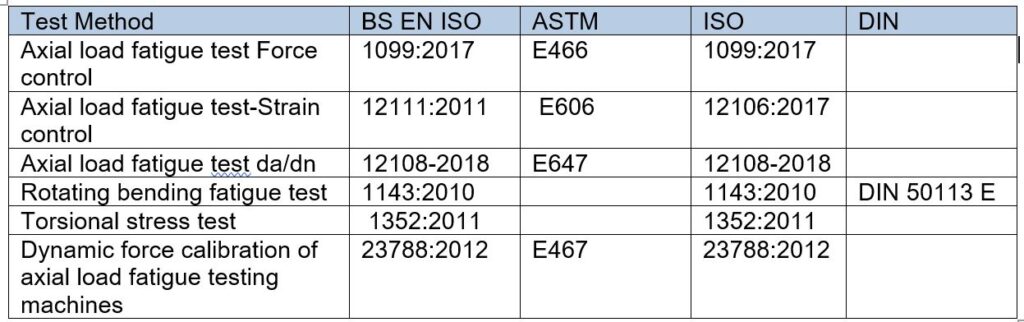

Materials used to manufacture parts that experience cyclic tensile service stresses are required to have an appropriate level of endurance and durability. Fatigue tests are carried out to establish the endurance limit based on either test specimens machined from the material or actual product endurance test work. The required test standards are shown in the Table below

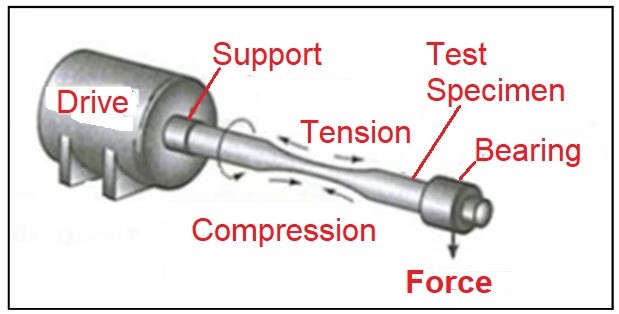

The fatigue properties such as the endurance limit can be determined using either rotating bending methods based on similar principles used for the early work carried out by Wöhler on rail axles. August Wöhler (1819 – 1914) was a German engineer. His work was regarded as the first to systematically characterize the fatigue behaviour of materials using the S-N Curves. He developed a machine for repeated loading of railway axles, and showed that fatigue failure occurs by crack growth from surface defects until the load can no longer be supported. A small machine for this type of test work is shown below.

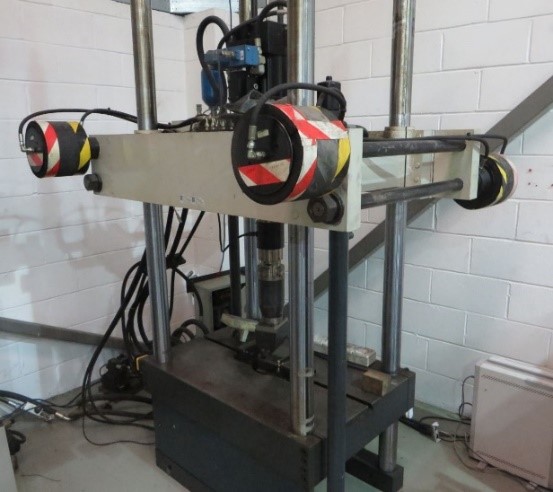

To carry out endurance work in the tension-tension mode requires a tensile load frame with either a servo-hydraulic actuator or resonant Amsler type machines. Typically, hydraulic machine can cycle up to a maximum frequency of 10Hz whereas the resonant machines can operate up to 150Hz and can therefore complete a large number of cycles in a shorter time. The photo below shows a Zwick Roel Ambler 20kN fatigue tester