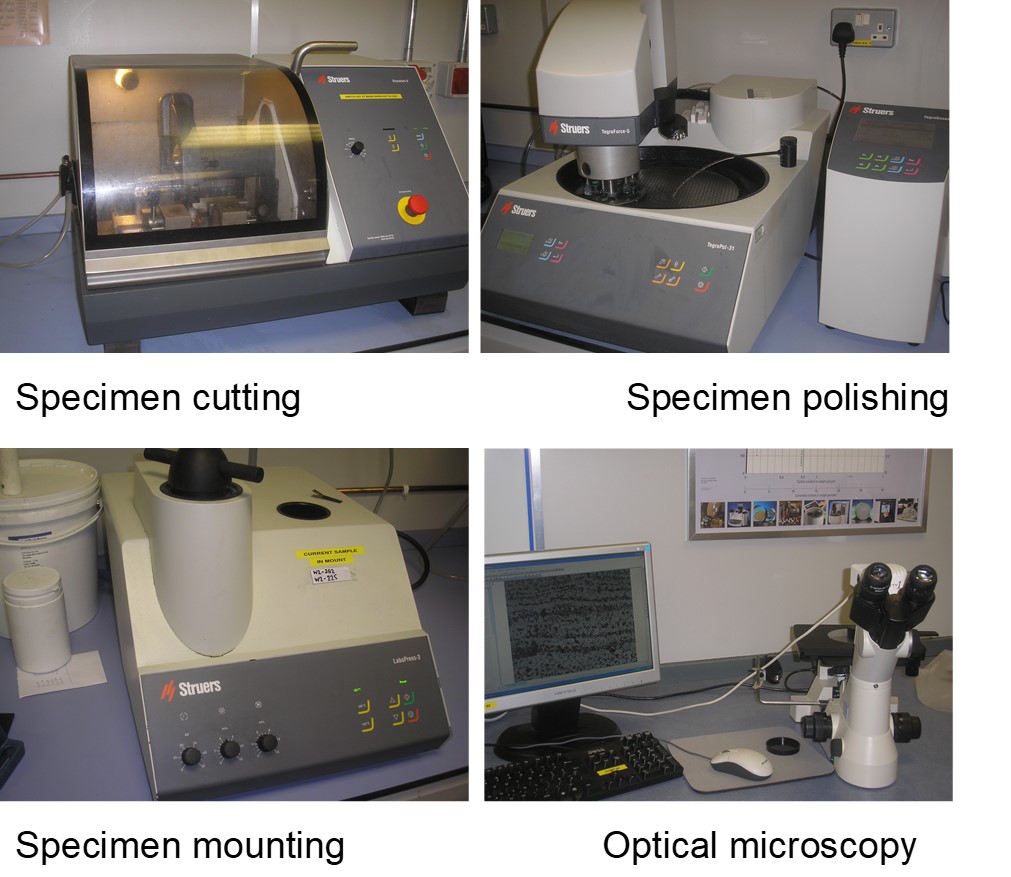

MSL have an extensive range of automated sample preparation equipment to enable timely sample preparation so that they can carry out examinations on both macroscopic and microscopic on most types of components and/or failures.

Macroscopic Examinations

In many cases detailed examinations of fractured surfaces can be undertaken using a low magnification technique. Hand lenses, binocular microscopes enabling magnification from 1x to 100x are available, along with macro-photographic facilities.

Microscopic Examinations

A range of optical microscopes are available enabling detailed metallurgical evaluation to be conducted up to magnifications of 1000x. The images can be magnified by a further factor of 2x by a colour camera linked through proprietary software to a colour monitor enabling storage of images to hard disk. This method of data storage is particularly useful for transfer to Word documents for subsequent report writing.

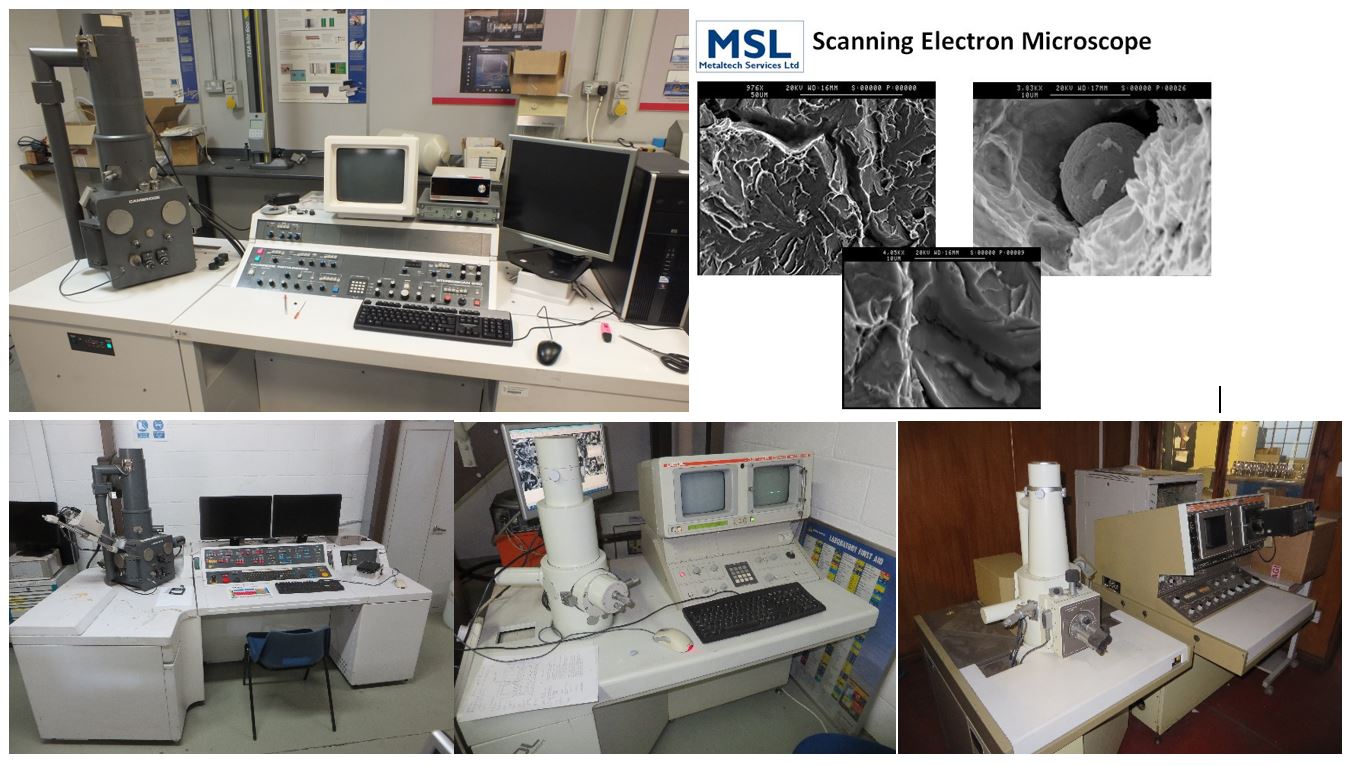

Scanning Electron Microscope (SEM)

The addition of a SEM to our list of test equipment allows a significant improvement in the ability to determine the causes of non conformities.

The equipment has the capability of high magnifications and allows images in the range 30 to 50,000 to be achieved. In addition the equipment has I-Scan digital software allowing digital imaging and image storage thus enabling transfer to a wide range of Windows applications.

A Polaron coating unit is available enabling coating of non conducting specimens by precious metal and carbon thereby allowing the equipment to be used on a wide range of applications.

Fractographic Analysis

Fractography is a descriptive explanation of a fracture process, usually in metals with specific reference to the use of photographs to study the fracture surface.

Macro-fractography involves low magnification (<25x)

Micro-fractography involves higher magnification (>25x)

The scanning electron microscope is a very popular tool in the field of fractography. The large depth of focus, the ability to vary magnification over a wide range, the non-destructive nature of the examination and the 3D appearances of SEM fractography makes the instrument an indispensable tool in failure investigations.

Several clearly unique and recognizable features of a particular fracture surface enable the failure mode to be established by the investigator.

Common features include:

- Dimpled fracture surfaces – ductile mode of failure. (Ductile rupture)

- Cleavage facets, indicative of trans-granular brittle fracture. (Cleavage fracture)

- Brittle inter-granular fracture – temper embrittlement, inter-granular S.C.C, hydrogen embrittlement.

- Fatigue failure striations.

MSL offer a comprehensive range of metallurgical analysis services, for further details please contact us:

For the full list of our UKAS Accredited testing please select the link below: